FAQ

This is a difficult question because we really don't want to recommend any of the currently made machines. They are all made in China and of very poor quality, some even more so than others. The cheapest machines available can be purchased for as little as $500-$700 but there is a 50/50 chance that the unit will show up dead on arrival. If they do arrive in a working condition, the expected life time of one of these machines is ess than 6 months.

The slightly more expensive units are generally worth the money. If there is one brand we favor it is the Kolice brand. These were the first machines we worked on and our first impressions were that they had issues. While we still think they are inferior to our Arctic Griddles, we are no longer manufacturing our units following the pandemic, and therefore if you are looking to purchase machines these are your best bets.

We still recommend that you purchase them through Amazon so that if there is an issue with your machine when it arrives that you have some recourse. The links below will take you to our recommended machines

We get this question several times a week. The customer complains that the unit has been working just fine for months then all of a sudden it starts taking longer to cool down or the unit cools down but cannot reach the set point. While it could be something serious like a loss of refrigerant or a damaged compressor, it is almost always a lack of air flow across the condenser coils. There are two main causes of poor air flow, an external blockage or dirty condenser coils.

First, an external air flow blockage may not be obvious. All rolled ice cream machines have an input vent for cool air and exhaust vent for the hot air coming from the condenser coils/fan unit. The blockage is often something as simple as someone placing a garbage can or other piece of equipment in front of either the intake or exhaust vent. Less obvious is when a new unit is placed in the same vicinity as an existing one. If the hot air exhaust from one unit feeds into the cool air intake of the second unit, it effectively chokes off the needed cool air to the second unit, causing it to run poorly.

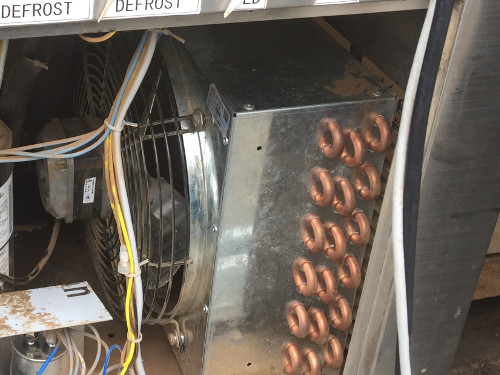

The second and most likely culprit of poor air flow is that the condenser coils are dirty and the air simply cannot pass through the them. Where the dirt is likely to build up the most is on the fan side of the condenser coils. The two pictures below show the condenser coil and fan units. Similar coils/fans are used in every rolled ice cream machine. The problem is that cleaning the area between the coil surface and the fan can be quite challenging because of a lack of access. As can be seen in the condenser coil photo on the right, the fans often have protective shrouds over them which makes cleaning the dirty coil surface almost impossible. In many cases the fan may need to be removed entirely or a small section of the protective should may need to be cut out such that a flexible brush can reach the coil surface. An alternative approach, but usually less effective, is to blow a large volume of air from the NON-fan side of the coils back to the fan side. This will often dislodge a large amount of the dirt from the coil surface. Don't try to blow air from the the fan side of the coils through to the other side. The majority of the dirt and large debris, such as hair, simply cannot be forced through the coils.

One question we are asked frequently is whether you should buy single or dual pan units? We strongly believe you should avoid all dual pan units no matter what. While there are some potentially nice or convenient features of the dual pan units, there is one significant drawback. When (not if but WHEN) one pan stops working you are left with a difficult decision, replace the entire unit or deal with half the machine just taking up valuable shop space. In some cases, both sides are also tied together, meaning if one side goes down it will also take down the other side. For us the decision is easy, stick with single pan units and you don't have to worry about the problem. All of the addon features of dual pan units can also be implemented in more flexible and user friendly ways. For example, the small cold storage bins found on some units can be purchased in separate machines that can then be located anywhere. Likewise, the separate refrigerator like storage box on some units (although often sold as refrigerated, are not actually) can be replaced with a standalone minifridge that actually is refrigerated.

UPDATE (May 10, 2019): One of the most problematic issues we have been hearing from some customers about their cheap Chinese machines is that they are seeing metal shavings in the ice cream rolls. Since we first started helping individuals through our www.rolledicecreammachines.com website, we've had customers asking about problems with the metal coming off their cheap Chinese made pans and ending up in their ice cream. While we talked to many different customers and tried to come to a concrete answer, we've only recently come to a definitive answer on this particular problem.

If the scraper is made of a harder material than the pan you will likely see small traces of metal in your ice cream rolls. It does not matter what the two materials are. So why then is my stainless steel 304 scraper causing metal to come off my stainless steel 304 pan? Not all stainless steel 304 is of the same hardness. Stainless steel 304 most often comes in a hardened (tempered) state known as annealed, which is its softest state. This is the preferred state for rolled ice cream machine manufacturers because it is the easiest state to form the material into the ice cream pan, whether it be through metal spinning or metal drawing. However, for the scrapers, making the scraper out of a harder material is beneficial. The hard material allows for the scraper to hold a sharp edge longer than if it was made out of a softer stainless steel. It's this difference between these two requirements can setup a potential problem.

So why not just make the pan out of a really hard stainless steel? There are multiple reasons why you don't want to use a harder 304 version. First is cost, the harder tempered state 304 costs more for the raw materials simply because of the additional processing that is required to work harden the material. Secondly, the costs to form this material into the pan then also increases. Lastly, let's say the pan was made out of ¼ hard 304 at an additional expense, any other harder material can still cause problems with scraping the pan.

NSF guidelines also dictate which stainless steel materials can be used in what is known as the food zone, further limiting which stainless steels can be used. As a result, we don't see any benefit in using a harder 304 tempered material. Therefore, our recommended solution to not scraping your pans significantly is to use an appropriate scraper. If you notice a particular scraper is putting metal in your ice cream, simply look for a different one that doesn't. While there are scientific ways of determining the hardness of a particular scraper, they require equipment that most people don't have access to.Our recommendations for a quality scraper are these from Kolice. They are the perfect 3" wide, have a straight scraping edge, and the stainless steel material has been tested to not gouge softer pan top metals - which shows up as metal coloring in the ice cream.

We've received a lot of questions regarding the need for temperature control. Many of the cheaper units on the market do not include a temperature controller. They are set at a fixed temperature, often colder than most people would like. As a result, the user must modify their ice cream mix to lower the freezing point of the machine. In our opinion, this is not the best way to go. We believe the temperature control option is critical to maximizing your profit. When you can adjust your pan's temperature you can work with different bases and foods, for example you can directly roll things like yogurts and egg nog. Likewise, if you want to do liquor infused, you'll need to set your pan temp lower to account for the lower freezing point.

This is a fairly involved question. There are multiple ways to make a rolled ice cream machine work. We've posted refrigeration schematics and description of how the different machines work over on our site Arctic Griddle - How An Ice Cream Roll Machine Works