Rolled Ice Cream Machine Airflow Problems and Solutions

Airflow related problems are the most common issues we are asked about with rolled ice cream machines. Sometimes the problems are clearly evident to the client, other times not so much. When your machine stops cooling down and the air around it is running uncomfortably hot, it's easy to understand how poor airflow could be a cause. Less evident is when you have a machine in a certain location that keeps failing, but temperatures around the unit don't seem unusually hot. Both of these situations can be the result of airflow problems.

A common scenario we encounter are shop owners who contact us the first hot day of the season about various problems. When the shop first opened for the year the outdoor temperatures were cool and the demand for ice cream was less so not all of the shop's machines were running at the same time. That all changes though once it gets nice out. Now, the outdoor temperatures are rising and all the machines are being utilized. The sun starts to come through the windows in the afternoon and all of a sudden the machines stop working. Knowing how to identify and resolve such problems is critical for any shop owner because all will experience issues at one time or another. First, we will look at the problems. Then, focus on what can be done to minimize such issues.

What happens to your machine without proper airflow?

Proper airflow is critical to making your machine run and keep running. When your machine is running, the compressor inside is compressing the refrigerant to a high pressure. This process of compression creates a significant amount of heat that must be removed from unit's internal condenser in order for the entire refrigeration cycle to function. In addition to the heat of compression, all of the electrical energy used to drive the compressor is also converted to heat that must be removed. The average amount of heat that must be removed from your typical ice cream roll machine is nearly 2000 Watts. Significant airflow through the machine is required in order to remove this heat.

So, what happens when your machine loses airflow? It depends largely on how much airflow is still present. With only some reduction in airflow the first thing that will start to happen is the internal high side pressure of the refrigeration system will start to rise. Most clients will never notice when this is happening since most machines on the market don't have a way of monitoring this. As a result of this rise in pressure, the compressor must work even harder given the higher compression ratios. What this means for you is your machine will start to put out even more hot air and your electricity bill will start to go up since more power is required to make the compressor run. For the most part though, your machine will continue to run. This is the state in which most machines are currently operating, which is less than ideal. Some common causes of a small loss in airflow are dirty condenser units and putting something too close to either the machine's cool air intake vent or the hot air exhaust vent.

Unfortunately, most people won't detect that an airflow problem is even present unit it becomes too late. The first signs of such issues are a reduced cooling capability of the pan (therefore longer time to make ice cream) and the air around the machine becoming uncomfortably hot. In some cases, the machine may shutdown altogether due to a tripping of either the high side safety pressure switch or the compressor's over-temperature limiting relay. In machines that have fuses, the fuses may also blow as a result of the much higher operating current by the compressor at these temperatures. Unless your machine is fitted with sensors to detect these conditions, there is a strong likelihood that permanent damage is being done to your machine at these elevated internal operating temperatures.

Why are high internal temperatures so bad? Besides the facts that high internal temperatures make the machine run less energy efficient and it takes much longer to make the ice cream, the most serious problem is the oil breakdown within the refrigeration system. At elevated temperatures within the compressor and refrigeration system, oil begins to lose its lubricating capability and will eventually breakdown. This turns the oil into an acidic sludge that plugs small openings and will eventually eat through the insulation of the compressor wiring. As a result, many different failure modes are now a possibility. It's not uncommon for people to contact us whose compressor has locked up or whose unit is completely blocked by oil in the capillary tube or filter.

So what causes such high temperatures? Some causes are obvious, some not. When you suspect an airflow problem, the first thing to check is the most obvious - the condenser unit. The condenser unit is the box-like component inside the machine with a fan mounted on it. Air blows through this to remove the system heat. It should be cleaned periodically so air can flow through it freely. How often it needs to be cleaned depends on how dirty the environment in which it is operating. For example, a clean storefront will require less frequent cleanings than will a machine that operates in a dusty outdoor environment. A condenser unit which is slightly dirty will cause the machine to run somewhat hot, but it will keep running. If allowed to get dirty enough, it will block all airflow and can lead to complete failure of the unit. So, please pay attention to proper cleaning of your machine. This is easier on some machines more than others.

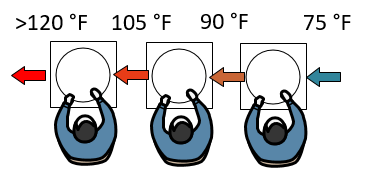

The most severe overheating problems usually are the result of how the machines are laid out within the shop or mobile unit. Each machine will have a specific direction of airflow, whereby cool air is expected to enter on one side, and the hot exhaust air will exit on the other. Some machines will have an air flow direction of front to back, but most are side to side. Regardless the type, make sure that plenty of space (12" or more) is free in front of both the input and output side. The most problematic scenario we see is when business owners put multiple machines side by side. What happens is one machine will pull in room temperature air into its intake and will exhaust an air temperature which is 10-15 degrees F warmer than room temperature. This elevated temperature air is then fed into what is supposed to be the cool intake of the machine next to it. This will cause this second machine to already run at elevated temperatures. The exhaust air from this second machine will then be another 10-15 degrees warmer than the air coming into to it. The much higher air coming out of the second machine then goes into a third machine. The third machine, taking in the very hot air, is almost certainly to have problems. If the overall shop temperature is cool, then this third machine might still be operational, but if the ambient air temperature goes up for any reason, this machine will be the first to shut down and have problems. See the picture below for such a situation. To make the problem worse, we have found that the second and third machines in the chain will have condensers that get dirty faster than the first because they are intaking the dirty air exhausted from the first.

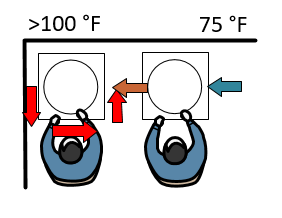

A second common problem we see are with corner units. A business owner puts a machine in a corner, whereby the airflow is exhausting the hot air into the corner. In this situation some of the hot air has nowhere to go but cycle back around to the air input, causing a positive feedback situation, whereby the machine will self-overheat. When a client contacts us about a failed machine, the first questions we ask are: Is the unit at the end of a machine line or is it in a corner?

How to minimize your airflow problems

The most important things you can do to minimize your airflow problems are to be aware of them and try to plan for them early on in the layout of your shop. It is much easier to design a proper layout than it is to try to install fixes after the shop has been fully established. So, what should be considered?

Airconditioning is an often-overlooked part of the airflow equation. An air conditioning unit that has worked well previously in a space might be significantly undersized after installing a few machines. Each machine adds nearly 1000 Watts of heat generated by the compressor into the space. When you multiply this by several machines it can quickly overcome the ability of the air conditioning unit to properly cool the space. This starts a chain reaction where the machines run less efficient, putting out more heat, and the air conditioning runs continuously trying to keep up. Ultimately the shop temperature rises, it now takes longer to make each ice cream roll, and both your customers and your operators are uncomfortably hot. In some of these scenarios we've seen the air conditioner could be upgraded, in others it was not an option. Where they were upgraded it came at cost of $5000-$10000, not a dollar amount you want to be surprised with when starting a small business. So, what other options are available?

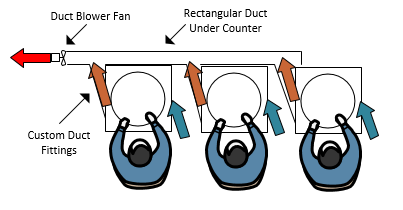

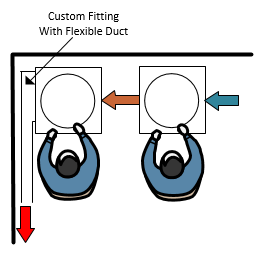

Arctic Griddle LLC has recently begun testing a range of ducting options to the machines in order to mitigate air flow problems. Installing ducts opens a wide range of options for improving airflow issues while simplifying layout constraints. For example, a duct can be installed from the exhaust output of a machine so that the heat generated can be vented to an area away from the machines. In some cases, it may even be possible to vent the hot air outside the shop or mobile unit, provided adequate make-up air is available. A duct booster fan can even provide more airflow to suck out the exhaust. Another option is to run ducting to the input of the machine which brings in cool air from outside the machine operating area. This prevents the machines from circulating their own hot air. The nice thing about ducting options is the flexibility. While one should consult with a local HVAC expert and your local business codes, a properly designed duct system should be capable of solving most airflow related issues and providing additional benefits including:

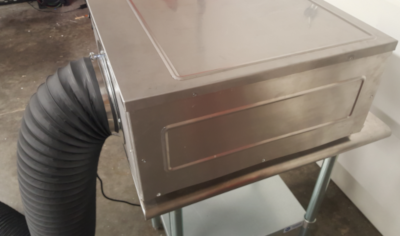

The following diagrams show how the above layout issues can be resolved using different duct options and custom-made duct fittings.

The most challenging part of setting up with a ducted system is finding the appropriate fittings to couple your rolled ice cream machine to the ducting system. Arctic Griddle LLC can help by fabricating these pieces for just about any rolled ice cream machines on the market. Below are pictures of two such ducting pieces, one for a common Chinese made machine and one for our Arctic Griddle portable machines.

Conclusion

Airflow problems with your machines and the overall layout of your shop can have detrimental effects on your business. These issues, however, can largely be avoided with proper planning and design up front. For shops currently experiencing such issues, there are solutions. Arctic Griddle LLC can fabricate custom duct fittings and ducting solutions which can help mitigate or eliminate most airflow problems. By eliminating these issues you can extend the life of your machines, reduce your electricity bill, reduce the time to make each ice cream (increasing throughput and profits), all the while making your business more comfortable for your employees and customers.