Home

Rolled Ice Cream Machine Technology Overview

Whether you call it Thai, fried, or rolled, this new style of ice cream is fresher and just plain better. That is why its popularity is taking off. As a result, the number of new rolled ice cream shops around the world are also exploding. Rolled ice cream is perfect for store fronts, food trucks, catering businesses, and any special event. For businesses looking to sell ice cream rolls the most important pieces of equipment you will purchase are your pans, yet little to no information is available for the first time buyer. Even for those with experience in the business there is much to consider when looking for new machines. This site is dedicated to providing information on all of the critical aspects to consider when purchasing your pans. We've also provided a page specifically covering some of the common problems we've encountered in repairing the really cheap pans purchased from overseas and how to fix them when possible.

#1 Reliability

We have listed reliability as the #1 consideration because your pans are your most important pieces of equipment. If your pan goes down so may your entire business until a replacement can be delivered. Since most units will ship from China, this may take 4-8 weeks. The bad news here is that the reliability of all units currently on the market (coming from China) is poor at best. That is how we (Custom Circuit Solutions LLC) became involved in the rolled ice cream business. We were brought in to repair and replace the electronics for a local fried ice cream business who's machines had all failed in one manner or other in less than a year.

There are three or four primary manufacturers of rolled ice cream pans, all based in China, that re-brand and distribute their units through numerous avenues. All of these vendors claim to have the highest reliability units even though they are often manufactured by the same company. The various manufacturers are easily identified by looking at the control panel on the front of the unit. Regardless of the manufacturer, the reliability is always poor. The typical lifespan of these machines is 6 months to a year. We've seen problems with all manufacturers. Their goal is to sell the cheapest product possible, not one that is of high quality. Some of the problems we commonly see are sticking mechanical relays, stuck compressors, loose connections, and blown compressor run capacitors. We've dedicated an entire page to the most common failures we've seen and how to resolve them when possible.

Our new Arctic Griddle line of ice cream roll machines is the only brand of machine designed for high quality and high reliability. We've dedicated an entire page to the address the lengths that we've gone to to make the most reliable product possible.

#2 Pan Top

The pans usually come in either square or round form. Examples shown below.

The average dimensions across for the pan can range anywhere between 12 and 22 inches. So which is better and what size do I need? We used to say on here that the choice between a square and round pan was mostly left to personal preference but that we recommended the square units for several reasons. While all of reasons we stated earlier in favor of the square pans still hold true, in developing the Arctic Griddle we have been made aware of several facts that now make us favor the round pans.

First, let's address why we initially believed the square pans were superior. Anyone that has rolled ice cream before knows that just prior to rolling, the frozen mixture is spread out evenly in a square or rectangular shape so that a specific number of even sized rolls can be made. So, if you have a round pan, that means only the inner square area is utilized and the rest of the pan area is essentially wasted. Mathematically, a square pan has 33% less surface area that requires cooling than a comparable round pan, making it more energy efficient. A second benefit of square pans is that the square itself helps guide the less experienced roller to spread the frozen mixture over a specific area. So then, what size do I need? We recommend a square pan of 15 or 16 inches across. That will produce 5 consistent rolls of 3 inches in width. This fills most standard size ice cream cups well.

So why then is the Arctic Griddle shipping initially with round pans only? It comes down to sanitation and cost. National Sanitation Foundation (NSF) guidelines require certain minimum inside corner radii in order for proper cleaning. In other words, sharp angles in the pan top are hard to clean and do not meet NSF standards. With all of the square pans we've come across, the tops are fabricated using a process of bend and weld. This process has two NSF problems, the bends are usually too tight to meet spec and the welds are not polished to the required smoothness. The reason square pans are fabricated this way is because it is cheap. A proper NSF certifiable square pan top can be created in several other manufacturing processes but the tooling costs typically run in the $10,000 - $20,000 dollar range, with large minimum order buys required. This makes a proper NSF certifiable square pan out of the reach of most manufacturers. A round NSF certified pan is much cheaper to fabricate because it can be made using a process known as metal spinning. For small manufacturers actually trying to meet NSF sanitation guidelines, a round pan is really the only viable option. With a round a pan, a slightly larger pan is required since some of the outer circle is not typically used in the rolling process. Our experience has shown that most customers are satisfied with a 20" round pan.

What else is there to consider with the pans? The pan surface should be constructed out of stainless steel, either 304 or 316, in order to meet NSF requirements. However, just being fabricated out of stainless steel is not enough to meet sanitation guidelines. If the stainless steel surface is heavily scratched and pitted it does not meet the NSF requirements. Some manufacturers ship pans where the surface is initially polished, others ship with very rough and scratched surfaces. Something else to consider is that for higher quality units that ship with well polished pans the surfaces will become scratched and pitted from normal wear and tear of the rolling/scraping process. Therefore, it is recommended that all units have their pan surfaces refinished periodically. A smooth surface is not only more sanitary but it also improves rolling.

One of the most problematic issues we have been hearing from some customers about their cheap Chinese machines is that they are seeing metal shavings in the ice cream rolls. Since we first started helping individuals through our www.rolledicecreammachines.com website, we've had customers asking about problems with the metal coming off their cheap Chinese made pans and ending up in their ice cream. While we talked to many different customers and tried to come to a concrete answer, we've only recently come to a definitive answer on this particular problem.

If the scraper is made of a harder material than the pan you will likely see small traces of metal in your ice cream rolls. It does not matter what the two materials are. So why then is my stainless steel 304 scraper causing metal to come off my stainless steel 304 pan? Not all stainless steel 304 is of the same hardness. Stainless steel 304 most often comes in a hardened (tempered) state known as annealed, which is its softest state. This is the preferred state for rolled ice cream machine manufacturers because it is the easiest state to form the material into the ice cream pan, whether it be through metal spinning or metal drawing. However, for the scrapers, making the scraper out of a harder material is beneficial. The hard material allows for the scraper to hold a sharp edge longer than if it was made out of a softer stainless steel. It's this difference between these two requirements can setup a potential problem.

So why not just make the pan out of a really hard stainless steel? There are multiple reasons why you don't want to use a harder 304 version. First is cost, the harder tempered state 304 costs more for the raw materials simply because of the additional processing that is required to work harden the material. Secondly, the costs to form this material into the pan then also increases. Lastly, let's say the pan was made out of ¼ hard 304 at an additional expense, any other harder material can still cause problems with scraping the pan.

NSF guidelines also dictate which stainless steel materials can be used in what is known as the food zone, further limiting which stainless steels can be used. As a result, we don't see any benefit in using a harder 304 tempered material. Therefore, our recommended solution to not scraping your pans significantly is to use an appropriate scraper. If you notice a particular scraper is putting metal in your ice cream, simply look for a different one that doesn't. While there are scientific ways of determining the hardness of a particular scraper, they require equipment that most people don't have access to.#3 Air flow

One of the most overlooked issues when looking to purchase new rolling pans is that of the machine's required air flow. Without proper air flow around your unit it will not cool properly, it will run horribly inefficient, and could be a safety issue if the unit is not equipped with the proper safety devices.

UPDATE: November 16, 2019: In our years of working with rolled ice cream shop owners from around the world, the most common issues we are asked about are related to airflow and overheating. Because of this we have added an entire page dedicated to the issues and what can be done to resolve them. If your shop is running hot, if you have certain machines in your shop that keep failing, or if it's just taking longer to make each batch of ice cream, click here to see how we can help.

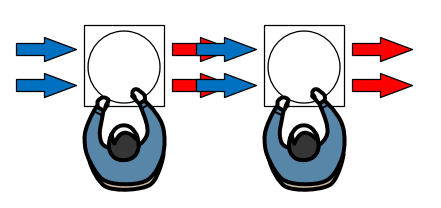

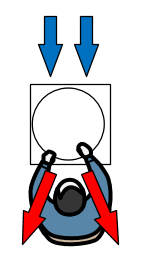

The average pan must vent nearly 2000 Watts of heat. It's important to understand where this hot air will vent to and where the cool air intake is. The hot air is rarely vented out the back of the unit since it is likely to be against some sort of counter and facing the customers. Now, if the air is vented out the front where the operator is, it can be quite uncomfortable working in front of the machine all day long in the heat. The only other option is to vent the air out the side of the machine. The problem with this approach is that most manufacturers require a minimum of 5-6 feet of clearance in front of the exhaust side. That means that you can't place a second pan or any other equipment side-by-side. So, whether you should select a front vented unit or a side vented unit depends on how you plan to lay out your various pans.

Lastly, proper air flow of your unit depends on maintaining the cleanliness of the unit's condenser coil. Being able to access these coils is vital. When looking for a new unit be sure that the coils can accessed without requiring complete disassembly of the unit.

The airflow of the Arctic Griddle can be configured for either front-to-back or back-to-front. This is because the airflow vents on the back of the unit are louvered (angled) downwards which prevents the hot air from blowing outwards towards the customers. We actually recommed the airflow of the Arctic Griddle be configured for this direction because it eliminates any hot air blowing on the operator and the machine will operate slightly more efficient. The Arctic Griddle was also designed to support fast and complete cleaning of the condenser coils. Check out our user manual for details. We will also be posting how-to videos on our YouTube channel. Please support us by subscribing here for future videos: Arctic Griddle YouTube Channel

#4 Safety

What could possibly be unsafe about a rolled ice cream machine? Plenty!! While there are a few machines on the market that are NSF certified, we have yet to see a single one that was certified for safety by Underwriters Laboratory (UL) or other similar approval agency. Most state and local jurisdictions have laws that require the use of safety approved equipment. Even if there is no legal requirement, it might still be required by your insurance company. Despite this, these laws are often poorly enforced and some inspectors will often allow non-certified equipment since there aren't any certified units available. Still, if something happened as a result of using non-certified equipment you are potentially liable and your insurance company may not cover you.

What should I be looking for in terms of safety? There are two main issues we commonly see in the various machines. First, very poor wiring. The connections are often loose and the wiring unsecured. All it takes if for one of these energized wires to come free and make contact with the machine housing to cause serious damage. At a minimum, you should ensure that your machine is plugged into a Ground Fault Current Interrupter (GFCI) protected outlet in order to prevent bodily harm. Secondly, most machines on the market do not include any type of high pressure protection in the refrigeration system. Without this, there is the potential for an over pressure blow out or explosion of the various refrigeration components. We highly recommend that your machine include a high-side over pressure switch at a minimum. All it takes is for something as simple as a plugged or kinked capillary tube under high operating temperatures to cause a high-side blow out.

The two pictures below demonstrate some of the issues we've seen regarding safety. From the picture on the left, you can see just how poor and unsafe the wiring can be. Likewise, the picture on the right is of a connector that was so poorly terminated the company glued the wires to keep them in place. This is should not be done on a properly terminated connector but this is the standard with this particular manufacturer.

#5 Acoustic Noise and Vibration

Noise and vibration are inherent in any rolled ice cream machine. Every unit has two components which contribute to the noise and vibration levels, the refrigerant compressor and the condenser coil fans. If you are only operating a single small pan then the noise levels might not be of great concern to you. If however you are operating a business with multiple units you should be concerned with the acoustic noise as your place of business can be quite loud and annoying, to both your customers and your employees. Vibration is a concern for all pans since strong vibration levels will reduce the reliability of your entire unit and can quickly wear out the refrigeration system's brazed joints.

The single biggest contributor to your unit's noise and vibration level is the compressor used. Many of the units currently on the market use a 1 ton (scroll type) Panasonic or Panasonic knock off compressor. These are pure junk. Not only are they unreliable but they are also very noisy. But, what can you expect from a compressor that costs less then $50. Some pan manufacturers offer compressor upgrades to something better such as a reciprocating Embraco compressor. These units are much better all around and certainly worth the couple hundred dollars extra. Lastly, we have found that the small single pans with nothing else attached are the quietest units on the market. Why, because the large dual units or the single units with all of the extra storage buckets tend to rattle like crazy. With one of these you will be spending a lot time just trying to silence all of these annoying rattles.

#6 Portability

Another claim that all manufacturers make about their machines is that they are portable. But what does that really mean? To these manufacturers portability simply means it has wheels and you can roll it around your shop. But when the smallest pans on the market weigh 150 pounds and the largest units upwards of 400 pounds or more, these can hardly be considered portable. If you want to take your pan to say cater a special event (fairs, farmers markets, grand openings, weddings, parties, ... ) it can be quite a challenging task. You will likely need to haul your unit around in a trailer and need additional help loading and unloading it. There is no unit currently on the market that is truly portable, one that you can just pick up, throw in the back of vehicle and go to your event.

The Arctic Griddle AG-1010 only weighs 84 lbs and is small enough to fit on most counter or table tops. While one preson can lift and transport the machine, we require that two persons be used to lift the unit for safety purposes.

#7 Temperature Regulation and Defrost

You've set your pan's temperature control setting for -20 degrees Celsius. So what temperature is your unit actually going to operate at? It is pretty much anyone's guess. It all depends on the machine that you have. It depends where the temperature sensor is placed on the pan bottom, how accurate the temperature sensor is, how long the unit has been running, and where in the temperature regulation cycle the temperature is being measured. We've found that the temperature regulation is pretty poor, they can be off by as much as 10 degrees Celsius at any one time. Across the pan surface the temperature differential can be as much as 40 degrees Celsius when first starting up! If the temperature sensor is located in the middle of the pan where the pan cools fastest, it may quickly reach the set point but the surrounding area just a few inches away may not even have reached the freezing point yet. If you tried to tried to makes rolls under this condition you would find that the middle would roll fine but the outside edges would just melt. If the machine is allowed to run for a long enough period this temperature gradient will even out some but there may still be a difference of 10 degrees Celsius across the pan.

There are two methods used by the different machines for regulating the temperature of the pan surface. Some machine use a simple on/off control scheme. When the temperature sensor reaches the set point the compressor turns off. After the temperature has climbed a few degrees the compressor kicks back on to again begin cooling. How far the temperature is allowed to swing determines how often the compressor cycles. A large temperature swing is bad for making ice cream but cycling the compressor quickly is hard on it and will dramatically shorten its expected lifespan. The second regulation method keeps the compressor on the entire time. When the temperature reaches the set point a valve is opened which bypasses some of the hot refrigerant gas coming from the compressor directly back into the input of compressor. During this time the pan surface temperature drops. The benefit of this approach is that it keeps the compressor from cycling on and off. The downside is that the compressor never turns off and therefore the energy efficiency is much worse.

Having a defrost function on your machine is important for two reasons. First, the defrost can be used to quickly raise the pan temperature and help release the ice cream from the pan while rolling. Secondly, when the pan surface needs to be cleaned the defrost can raise the temperature of the pan above freezing, making it much easier to wipe clean. Make sure that the defrost function on your machine is implemented using the hot gas bypass method. When the defrost button is pressed it engages a valve which diverts the compressor's hot gas output past the condensing coils and injects it directly into the evaporator coils of the pan surface. This provides a rapid temperature rise so there is less waiting required. Other defrost methods such as electric heating coils are too slow to be useful.

We've received a lot of questions regarding the need for temperature control. Many of the cheaper units on the market do not include a temperature controller. They are set at a fixed temperature, often colder than most people would like. As a result, the user must modify their ice cream mix to lower the freezing point of the machine. In our opinion, this is not the best way to go. We believe the temperature control option is critical to maximizing your profit. When you can adjust your pan's temperature you can work with different bases and foods, for example you can directly roll things like yogurts and egg nog. Likewise, if you want to do liquor infused, you'll need to set your pan temp lower to account for the lower freezing point.

#8 Energy Efficiency and Power Requirements

Everyone should care about their pan's energy efficiency level. With your pan on most of the day and consuming nearly 1000 watts of power on average your electricity bills can quickly add up. When you have more than one pan it becomes an even greater issue. So what can be done regarding efficiency? As stated above, there are currently two modes of pan operation. If your pan's compressor cycles on and off to regulate temperature then it will consume roughly half as much as the units which stay on permanently and use hot gas bypass. The down side though as stated before, these units are less reliable because of the frequent compressor cycling. The other issue that effects efficiency is air flow. If you are operating two or more side exhaust units side by side then you are feeding the hot air exhaust of one unit into the cool air intake of the unit next to it. This causes the unit taking in the hot air to run horribly inefficient. Likewise, if your condenser coil is at all dirty then the air flow across it is substantially reduced and this too will cause a reduced efficiency.

The average power consumption for a rolled ice cream machine is nearly 1000 Watts, roughly 8 amps for a 120 Vac system. However, the starting surge amperage for one of these units can approach 100 amps for several cycles! Why does this matter? This high surge current is hard on all of the unit's and your building's electrical system. It is the main reason why units that constantly cycle on and off have such low reliability. This surge current must also be considered when planning how many pans to install in your new business. For every two operating machines, we recommend a dedicated 20 amp circuit powering them. Do not try to power three units on a 20 amp circuit. It might work for a while but it can easily trip the breaker depending on when the compressors cycle. Also, if you only have 15 amp circuits available we do not recommend trying to power more than one unit per circuit. Finally, if you are wanting to operate your pan off of a generator, keep in mind that the high surge currents will likely require that you grossly oversize the generator required.

#9 Refrigerant Type

The refrigerant type your machine uses is not that important. Just make sure that your unit does come with refrigerant. We've found many units are shipping without any refrigerant and it is left up to the end user to add the appropriate amount. This is not something everyone can do and most likely requires an expensive service call from a local refrigeration company. That is if you can find a service company that will tackle the task given that there is often little support or documentation from the manufacturer.

The two most common refrigerants that are used in the machines are R410A and R404A. R410A is slightly more efficient but is a high pressure refrigerant. All machines should come with a high pressure safety switch but few do. So, if your machine uses R410A it is even more critical that it has a safety switch to prevent a high pressure blow out. R404A is slightly less efficient than R410A but runs at a much lower pressure.

#10 Single VS Dual Pan Units

One question we are asked frequently is whether you should buy single or dual pan units? We strongly believe you should avoid all dual pan units no matter what. While there are some potentially nice or convenient features of the dual pan units, there is one significant drawback. When (not if but WHEN) one pan stops working you are left with a difficult decision, replace the entire unit or deal with half the machine just taking up valuable shop space. In some cases, both sides are also tied together, meaning if one side goes down it will also take down the other side. For us the decision is easy, stick with single pan units and you don't have to worry about the problem. All of the addon features of dual pan units can also be implemented in more flexible and user friendly ways. For example, the small cold storage bins found on some units can be purchased in separate machines that can then be located anywhere. Likewise, the separate refrigerator like storage box on some units (although often sold as refrigerated, are not actually) can be replaced with a standalone minifridge that actually is refrigerated.